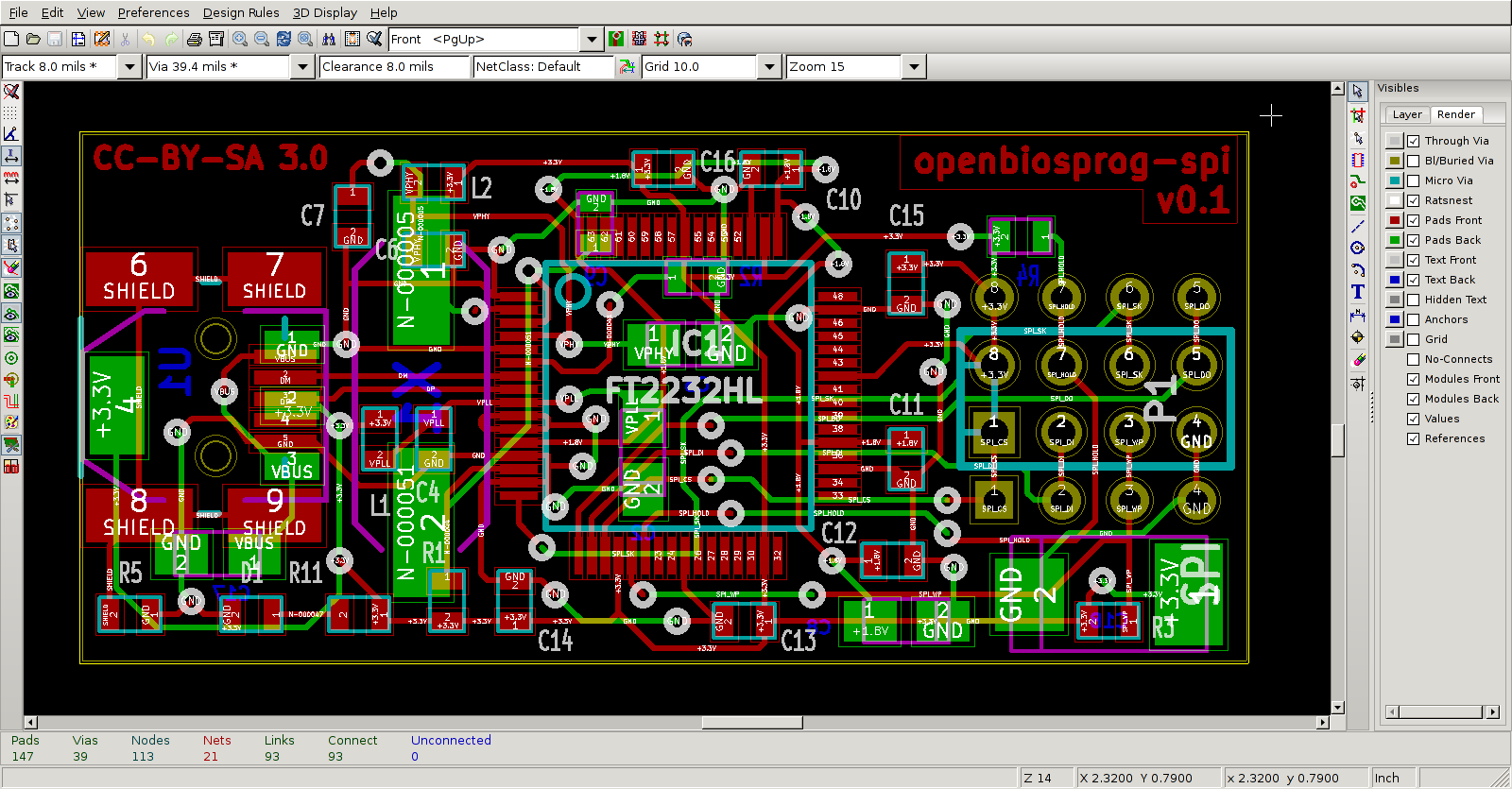

View your PCB designs in 3D with KiCad’s integrated 3D Viewer! Coupled with a large library of 3D models, you can instantly inspect your design in an interactive 3D view. Rotate and pan around to inspect details easier than with a 2D display. The ‘kicadpcb’ file contains layout information. The files with the ‘sch’ extension contain schematic information. There are two ‘sch’ files because this project includes two schematics. Project file and main window. Double-click on the ‘pro’ (project) file. The main KiCad window will appear.

In this tutorial, we will tell you about the steps to generate BOM(Bill of Materials) and CPL(component placement list, as known as a Centroid file/Pick and place file) in KiCAD.

Generating BOM Files

Kicad Pcb Project Download

The BOM or Bill of Materials file tells the manufacturer which components is installed at which position. For example, PCBs have positions like C1,R1,T1 etc. printed on it. But the manufacturer should know what value capacitor or resistor is placed at that location. This information is present in the BOM file and is very important for assembly work. BOM file is a simple text file in comma separated form (csv) but you can also make it in MS Excel or other spreadsheet programs.

As you can see in the above BOM file, we have first column Comment where we should describe the parts in as much detail as possible, the most important being the value of part say 0.1uF but you should also include tolerance, maximum voltage and other information so that the production staffs can pick the best possible parts for your project. Next column is the Designator, that means on which position this part should be placed and soldered. The next one that is the Footprint or package is also very important because SMD parts come in various sizes(packages) so the assembly staffs should know which package would fit in your PCB. You should be aware of common SMT sizes like 1206,0805,0603 etc. The last column is LCSC part number, now this can really help you speed things up and get accurate results. JLCPCB has a large stock of parts (more than 30,000) and each part has a part number. You can use this part number to accurately identify the part you need. Simply check if the part you need is in stock at JLCPCBs part library and add them as LCSC

field value to KiCAD

To export the BOM from KiCAD you first have to go to Arturo's BOM export script, download the Zip and unpack it.

Afterwards you can click on Export BOM

and add the bom script to KiCAD (1). Change the command from %O

to %O.csv

(2) and click on Generate (3). This will generate the BOM needed for assembly.

Kicad Flex Pcb

Generating Pick and Place files

Autocad 2015 for mac keygen. The CPL file has to be generated from the PCB editor, click on File

-> Fabrication output

-> Footprint position (.pos) file

and export the file with the following settings. Smart card reader application software.

In order to be compliant with JLCSMT you have to edit the CPL/POS file with Excel or libreoffice Calc.

The folling changes are required:

Ref

to Designator

PosX

to Mid X

PosY

to Mid Y

Rot

to Rotation

Side

to Layer

Open .pcb File Kicad

Before, as exported from KiCAD: After modifying the header: